What are the benefits of the ice building tank in a dairy business?

In this concise blog, our focus will be the ice building tank, its use, and its benefits for the industry. This will be an engaging blog to expand the horizons of readers, especially those directly or indirectly connected with dairy, food processing, and F & B.

Learning about the machine

The technology-driven machine uses a chiller to carry out the ice building process during off-peak nighttime hours as energy load falls. The ice produced is ready for peak period cooling requirements. As a result, minimizes power load and helps in the smooth functioning of the process plant.

Environmental benefits

As far as applications of the dairy ice building tank are concerned, the most important function of the modern machine is to shift on-peak electric load to off-peak. The machine has been immense environmental benefits as it substantially reduces air-polluting emissions. It's similar to reducing four and two-wheelers traffic for a while.

Is this a reliable option?

The way batteries are to electricity, IBT system is to chillers. Similar to the way batteries act as a backup for electricity, the dairy ice building tank works as a supplementary for chillers. At the same time, the machine reduces the risk of the transition between free cooling and mechanical cooling. Therefore, help your business operations during a temporary chiller shut-down. It may happen during a free cooling operation or other operational accident which leads to the temporary shutdown of chillers.

Advantages of the machine

Here are the benefits of the industry-centric machine:

- An energy-efficient machine

- Requires less connected power load

- The ice water intensively cools the product without any risk

- No need for power, the moment ice formation gets completed

- An ideal machine for storing cooling energy

- Cooling tower and water supply not required (for air-cooled type)

Special Features

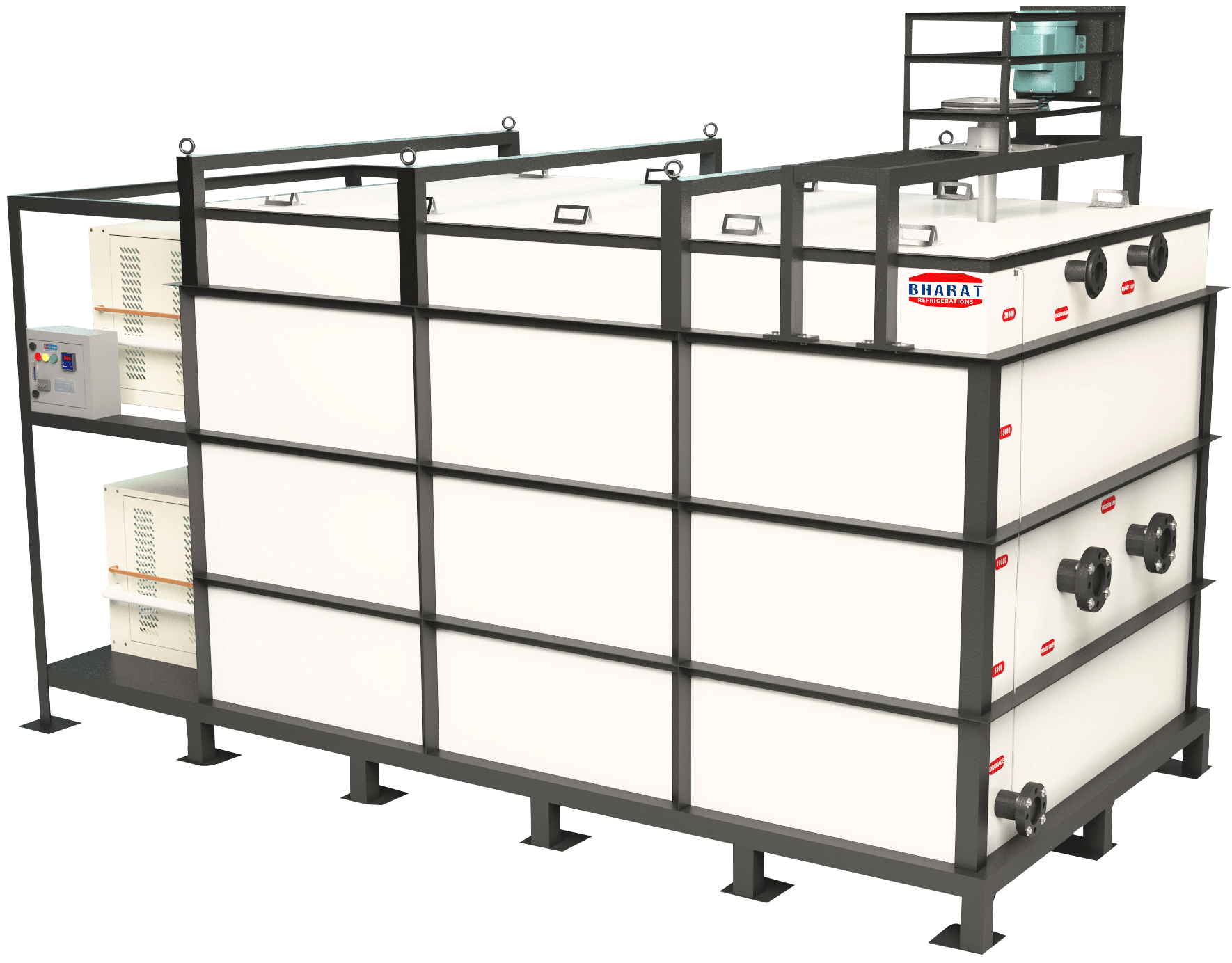

Moving forward, let's now focus on a few special features of the product. The machine is ready to install and use. Subsequently, a dairy firm doesn't require any specific construction or fabrication work to install the machine and commission. In this way, you are saving your hard-earned revenue. As far as shifting is concerned, the modern IBT system is easy to lift and shift. You don't require a team of a heavy workforce to move the machine from one place to another.

What about insulation?

Quality insulation helps your business to maintain the desired temperature for a long, protecting the machine against high extremal temperature. Without ideal insulation, the machine wouldn't be able to work efficiently. It's not over yet. In addition to this, insulation is also useful to reduce noise pollution.

Conclusion

If you are into the dairy business or managing a food processing company, the modern machine is going to serve numerous purposes. It’s is a machine worth to invest.

Custom-made designs

A few companies in India are competent to deliver custom-made solutions. If you are struggling to find the ideal machine for your company then connect with leading manufacturers in Ahmedabad, Gujarat.

End your search with Bharat Refrigerations

If you are looking for a dairy ice building tank with excellent quality, then end your search with Bharat Refrigerations.

Let's join hands

Bharat Refrigerations is a wholly-owned subsidiary of Ice Make Refrigeration Ltd., an acclaimed name in Refrigeration Products and Equipment since 1993. Our excellence-driven total cold chain solutions comprise Cold Room & Storage Room, Transport Refrigeration, Commercial Refrigeration, refrigerated container, Ice building tank, etc.

Let's collaborate for a mutually beneficial partnership and take your business to the next level!