Our Products

Chilling Plant

Catering to the demands of our clients, we are engaged in manufacturing and supplying of Chillers. Our range includes Air Cooled Chiller, Water Cooled Chiller, Liquid Chiller, Brine Chiller and Screw Chiller. Designed with the assistance of advanced technology, these models are cooling efficient and environmental friendly refrigeration systems. The compressor of the chiller is highly efficient and generates minimal noise during usage. These chillers have gained wide appreciation across various industries for cooling efficiency and longer functional life.

Air cooled Chiller

We are amongst the trusted manufacturers and suppliers of Air Cooled Chiller, a compact size portable model. These chillers are fully automatic with high quality controls, with chilling ensured with plate type, shell and tube evaporators. This dependable and trouble free equipment is provided with single, dual compressors for power saving. Specific designs for low temperatures are also available as per the client specific requirement.

Specifications:

Features :

Water Cooled Chiller :

We are engaged in offering Water Cooled Chiller that has gained wide appreciation for international quality standards. Designed with the assistance of advanced technology, these models are cooling efficient and environmental friendly refrigeration systems. Renowned for optimum performance our range finds wide application in machine, oil cooling, chemical, pharmaceutical processes cooling, comfort cooling and process water-cooling.

Specifications :

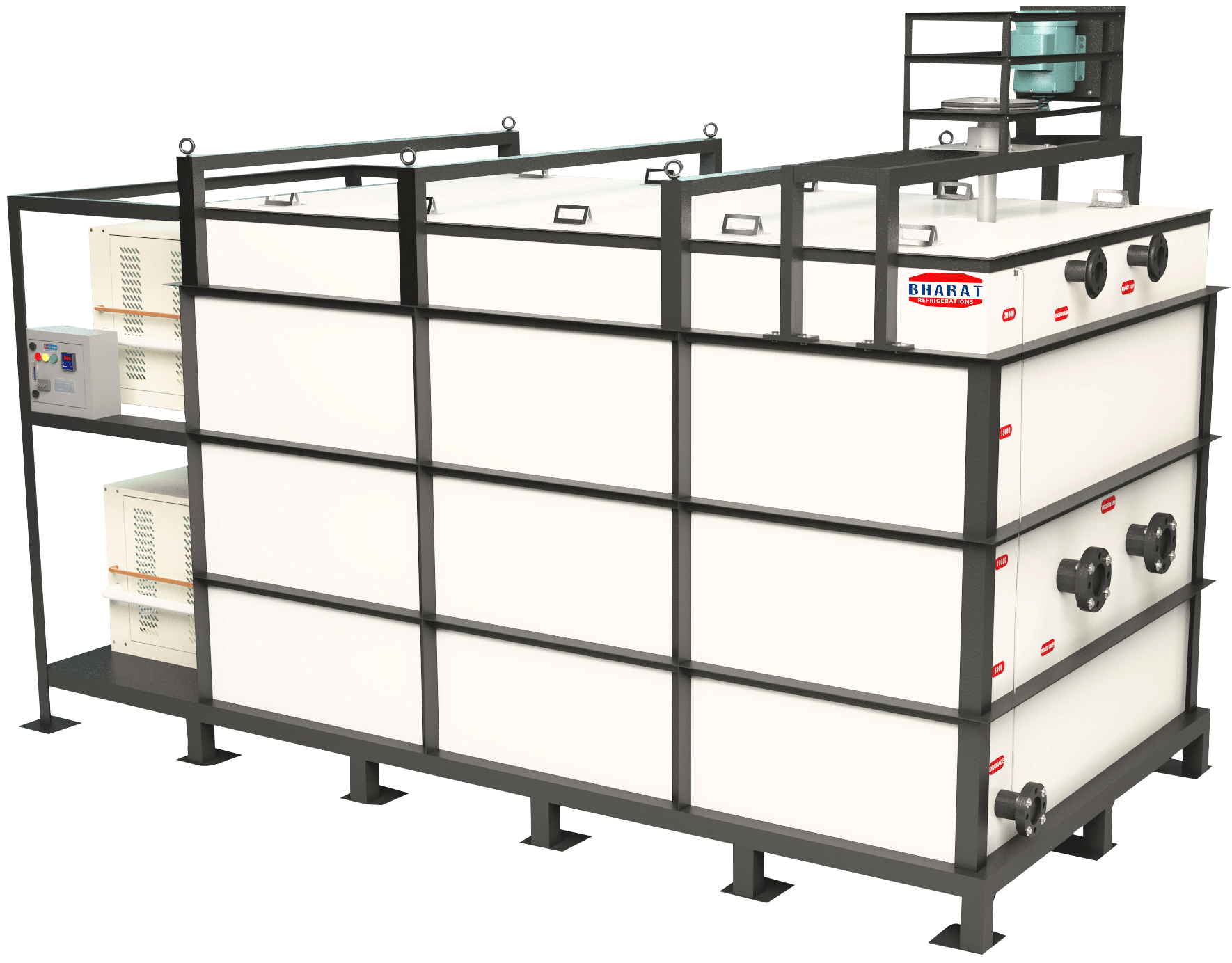

Ice Building Tank :

IBT is a system, which is store energy in the form of ice. It is applicable in dairy industry for quick process in short time with certain limit of power load.