Our Products

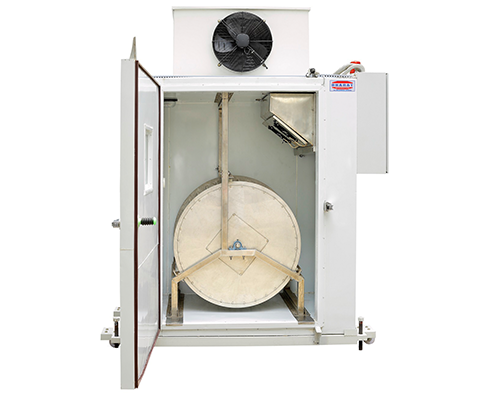

Hose Chiller

Bharat Hose/Capstan Chillers are basically to cool Hose before it passes on to the Braiding machine.The operations are simple and user friendly.

Rubber compound has both plastic & elastic phase and plasticity keeps on increasing while decreasingthe temperature and becomes very stiff or hard until it reaches to its glass transition temperature (TG).

This toughness helps extruded tube to hold the tension and settle all the wires uniformly on thesurface of tube which results in smooth appearance and accurate pitch.

HOW IT WORKS?

Bharat Hose/Capstan Chillers consist of an insulated chamber attached with an Air-Cooled andWater-Cooled Refrigeration system with R-404A refrigerant. The Hose that needs to be cooled passes inside the chamber. The cooling is obtained with the stream of cold air delivered on the Hose that exchanges heat so the hose is cooled to the desired temperature.

The setting time of the Hose in the refrigerated chamber can be changed accordingly to the diameterand the type of polymer used. Such a variation is obtained by increasing or decreasing the number ofspirals winded up around the special drum (Capstan) that is mounted inside the chamber.

The stream of cold air skims the hose and removes the heat from the mass till few centimetres before the meeting point between the hose and the reinforcing material, and it can be regulated as inside the chamber and inside the connecting “TRUNK”.

FEATURES

ADVANTAGES

The Hose Chiller is an alternative in all systems and methods till now known and it has the following advantages:

OUR VALUED CLIENTS

And Many More…